|

Diary of a dissatisfied customer | ||||||||||

The Problem This is not about British Gas or Cavity Wall Insulation per se. It is about the inferior cavity wall insulation job carried out at my home for which British Gas is responsible. The cavity wall insulation involved is one particular type and what applies to this particular type may not apply to other types of cavity wall insulation. British Gas supplied me with a document produced by the British Board of Agrément (BBA), a document which the British Board of Agrément had previously refused to supply me with. The said document will feature prominently in this section of the website, where I hope to demonstrate clearly why the work is substandard and why the document itself is substandard: I am a construction professional used to examining everything. I take nothing at face value and neither should you. Do not be dazzled by a fancy looking document. Look at the evidence. Look at the facts. For the avoidance of doubt, the cavity wall insulation product itself may be the best on the planet. This is not necessarily about the product used but installation of the product used, which is obviously beyond the control of the product manufacturer. History I have had to endure tragically pathetic and indeed naive arm-waving by British Gas and others during their efforts to befuddle or con me into accepting an unbalanced compromise. What are in my opinion classic commercial cowboy tactics. Latterly that has included trying to bring a product expert to talk to me. I do not at this stage have a problem with the product. The facts are plain for all to see and the response to those facts self-evident to any construction professional. There is a substantial void where there is no pre-existing construction reason for the void. Given the evidence below it is clear there will probably be further voids and given that information, the response as I have said is self-evident. The self-evident response will be implemented and cannot be avoided. I am devoted to energy conservation in order to save money on fuel and bring comfort in my later years. In connection with that I have invested a lot of time, effort and money. My money and only my money. Because of that I am not inclined to be fobbed off by corporate bullies who clearly have no interest despite the window dressing of their self-aggrandising public image. |

|||||||||||

|

|||||||||||

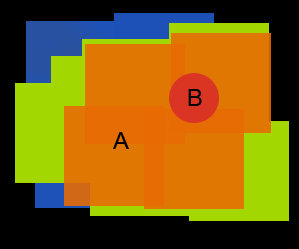

It will now be necessary to create a series of pages under this heading. The pages concerned will have a link back to this page only. You can either skip those pages for now or read them and return to continue reading this page. Using this technique will I hope aid understanding. I already know that the injection process itself is crucial to understanding the problem. Again we should not jump to conclusions as to the cause. We need to examine all available evidence. That evidence is surprisingly broad. For example it may or may not be the fault of the operatives carrying out the work. Unfortunately the BBA document is technically poor and answers are needed in connection with that. I have no doubt the previously experienced obstruction to my enquiries will continue and recourse to the County Court may ultimately prove necessary in order to obtain answers to questions posed about the process. We have to be on our guard against what may prove to be industry-wide collusion or corruption. If the latter applies we may never overcome that without official support and may need to seek an alternative cavity wall insulation material / process which reduces the risk of failure, for example beads or granules, as has already been whispered in my ear. The latter is being explored but first the process theory. At this point in time I do not have access to details of the training regime for key card-carrying operatives. That may or may not throw light on this subject. I do not have details of approved apparatus used for the work. That would also help. As a basis for discussion we will assume that a correctly trained operative was in control and all the correct apparatus and protocols were employed throughout the work. With this in mind we will examine what was actually carried out or as we say in construction as-fixed. With any investigation we have to be extremely wary of contaminating evidence. In this case evidence of failure is hidden from objective scrutiny by brickwork. However the matters that hinder objective scrutiny also protect the evidence from the risk of contamination or even sabotage. It is now self-evident that failures can occur with cavity wall insulation. There is irrefutable evidence of one failure already at my home. There may or may not be more. That said, the nature of the known failure is such that we cannot in any way be confident it is an isolated incident. As I paid for filled cavities I will settle for nothing less. The BBA document includes the following words: the Certificate holder oversees the activities of approved installers operating under the BBA Surveillance Scheme for Cavity Wall Insulation. It is a requirement that the system supplier undertakes a minimum of four inspections per annum to each installer using their product and maintains records. I received an inspection but there was no documentation associated with that inspection. I cannot therefore be sure what the inspection was related to. Internal or external audit. Either way the inspection visit was simply window-dressing for gullible punters, me being one of them. It should already be self-evident to any reader lay or otherwise, that the only viable method is thermography and someone wearing knee-pads.. The snag with that method is that it can be too good but we also need to be careful. Following considerable correspondence from me in the early days, British Gas eventually and reluctantly suggested random boroscope testing. What was meant by random was not stated. How objective that would be was not stated. I already know enough now (I did not before this started) to undertake a not-so-random test that could produce a result in favour of the contractor. I was also aware then of the commonplace use of thermography and the apparently moribund CIGA. |

|||||||||||

|

|||||||||||

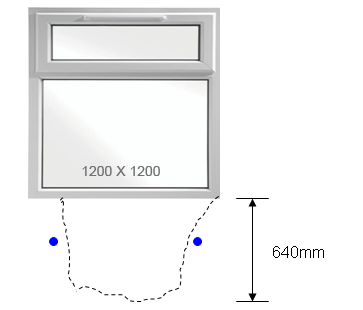

I am competent to consider contrasts on the same property with the help of the photographer. But first the images need to be taken and that also requires great care. Some suggest thermography is a job for insomniacs. It must be carried out on a dry day very early in the morning before solar gain has a chance to affect contrast. The photographer also requires heating on for 24 hours, all doors open, large items of furniture moved away from external walls and, my choice, I will also remove the bath panel which will otherwise prevent that area from receiving internally generated heat quickly. The wall there is already suspect according to the drilling pattern actually used. |

|||||||||||

|

|||||||||||

|

|||||||||||

ONGOING AND UNDER DEVELOPMENT WHILE THIS LINE EXISTS |

|||||||||||

| Top of Page | |||||||||||