|

Diary of a dissatisfied customer | ||||||||||

Analysis

|

|||||||||||

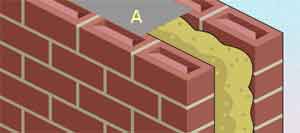

My priority is the cavity wall insulation. It is the only job I have not done myself at this house simply because I do not own the blowing machine equipment necessary including hoses and directional tip. I own access equipment, industrial drills and the skills for all. I am obliged therefore to rely on others who were paid to do the job in accordance with good trade practice and that British Board of Agrément (BBA) document. Ultimately the work will be done properly, one way or another. Ultimately British Gas will pay, one way or another. First we will discuss and dispose of one or two anomalies in the industry that I was not previously aware of. |

|||||||||||

|

|||||||||||

|

|||||||||||

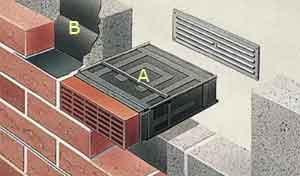

| The need for this is clearly specified in the BBA document and retrospective installation of ducted air-bricks is straight forward. It seems to me this is another case where the eyes and ears of industry are deliberately closed to the need. So, what happens if someone is hurt or a householder suffers an attack of Serpula lacrymans (dry rot) because air-bricks are choked with insulation. In the case of Serpula lacrymans the arguments would go on for years and the householder would eventually give up fighting a PLC. In the case of a sudden-death due to carbon-monoxide poisoning the operatives would, wherever possible, become the sacrificial goats. Either that or if there is a delay the insulation company might take the rap, shrug their shoulders, change their trading name and get on with it. |

|||||||||||

|

|||||||||||

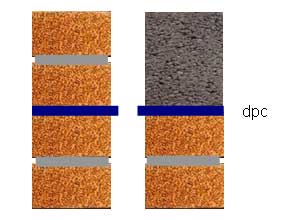

That of course is when the air-brick is below the dpc. When the air-brick is above the dpc, the air-brick may easily get blocked. Hence we need surveyors with knee-pads, toolbox and overalls rather than a suit. The same applies to inspectors. Whatever your point of view, the work should have been done and according the website of the moribund CIGA, contractors work to 'stringent' technical standards. When I asked for a copy of those standards, which clearly should be in the public domain, I was ignored. |

|||||||||||

|

|||||||||||

An address close to me had CWI as an official installation, then a neighbour received the same treatment for £100 cash. Once set up on site the installation work takes very little time. It is an opportunity for poorly paid operatives to earn a crust. However the insulation has to come from somewhere and someone must be being short-changed. At the end of the day the save-energy objective must be suffering and those paying the full fee are being ripped off.

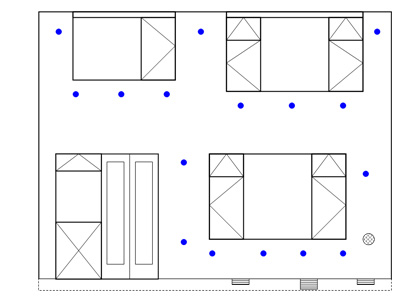

The snag is that we do not know whether operatives can tamper with the pressure and/or flow-rate delivered by the blowing machine. We do not know if discreetly restricting the hose somewhere can have the same effect. We do not know as I have mentioned before whether the directional nozzle should adopt a certain posture. IE always face downwards or upwards, or whatever. We are given a deal of information but not enough for anyone skilled in spotting fraud. Short-changing on CWI amounts to criminal fraud if it is deliberate. It is not a civil matter and perhaps the Police should be involved if CWI shortfall proves significant and no progress can be made. I draw no distinction between this slight of hand and the rogue trader on the door step trying to extract money from a pensioner like me for bodged work. Especially when they hide behind highfalutin claims and fancy certificates. The system as described should be - within reason - infallible. As it is it is clearly open to widespread abuse. As it is, it clearly is being abused. February 2013 - As they say in law res ipsa loquitur or, let the facts speak for themselves. At this point in time we now have the results of the endoscope survey and the thermographic survey. The evidence of incomplete insulation is widespread and overwhelming. It is clear that the work will all have to be done again. So it is now time for the next phase of this long-running saga. I need to know why the work carried out is so bad. I need to know how they will prevent the same happening when the work is redone. Unless you know how or why it happened, you can not take steps to prevent it happening again. One option for remedial work will be to use a fill product other than mineral wool. I now suspect the process for installation of mineral wool cannot be reliably safeguarded as it can with other products. Given I do not have access to data that would enable me to investigate the cause of such widespread failure, I will have to ask the people who do have that data. I have no choice. If or when they refuse I will have to crank up the pressure. The next phase will now have to be implemented. March 2013 - From examination of available information including endoscope and thermal image images (only samples have been published) it is now clear that whilst the drilling pattern for CWI may have been broadly observed (because they can easily be checked), that is not to say that all injection holes were utilised. Indeed it is impossible. Some injection points are now proven to be in the middle of major voids. A best guess at this stage is that the operative in charge has skipped some holes, possibly working to a well established pattern of deceit, in order to save time and insulation. I will still ultimately require an answer from the British Board of Agrément on which way the directional nozzle should be facing when it is being used in accordance with their certification model. There must be an answer and ultimately I will have an answer, then you can all have an answer. The matter is now recorded on the database of my local Trading Standards office. I have email confirmation of that. 15.03.2013 - I have now necessarily written to both the British Board of Agrément and the product manufacturer regarding remedial action required to correct the work. They have been served by Registered Post so I can refer to that as evidence if required. A copy of the body of the letter is available here as a PDF file. A few years ago I was asked by a company of housebuilders to investigate problems with heating systems at a new development. The systems had been designed by the boiler manufacturer’s own in-house designer. That was and still is standard procedure. The system designer had also been asked to report. However the marketing director, not the designer, wrote the report. That report for all practical purposes useless. The marketing director bluntly explained to me quietly that the contractor (a cowboy) was as good a customer in his own right as the housebuilder. This of course the real world of commerce. Why do I use the word ‘cowboy’ ? This is simply because the as-fixed installations were not even close to the design supplied by the boiler manufacturer, therefore no other word applies. It was and is obvious deliberate fraud. I had no trouble then identifying the fraud in great detail and producing a report accordingly. I have no trouble now in identifying fraud in great detail. The only difference is that on this occasion I am not being paid and I am the victim of the fraud; whoever is responsible it clearly now is fraud. 31.03.2013 - I received a prompt response from the BBA. Any delay posting here is down to me and my own ongoing commitments. I have responded to the (emailed) BBA response. A copy of both can be seen here. As is typical of all large organisations answers are fudged and designed to keep everything hidden from the fare paying public who have a right to answers. So we have to persist. Who are the BBA accountable to if not consumers ? They set themselves up as experts and need to take responsibility for decisions they make. They need to be transparent and be seen to be transparent. Modern homes have the head of the cavity sealed and in any case are insulated during construction under the Building Regulations. The large majority of existing homes being insulated will therefore be older and have no cavity head sealed (or air-bricks ducted). We are presented with a veneer of respectability by everyone involved in the industry when at the end of the day they all know or suspect the real outcome is far from respectable. It could be made respectable but no one is interested. 12.04.2013 – For the record the insulation material manufacturer has made contact this week. All I can say for now is that negotiations have started, if that is the right word. Obviously I have no contract with the product manufacturer but they are inextricably linked with the installer and the certification provider. What ‘inextricably linked’ means remains to be discovered. As I have mentioned above (15.03.2013), sometimes the supplier has a serious conflict of interest and the principal interest to industry is money. I confess I am not entirely free of such ‘forces’. It is necessary for me to maintain expensive certification under different headings, both qualifications and apparatus, in connection with my work. That word expensive ensures I am treated with greater deference than I would be if I walked into a wholly impersonal and impartial lecture hall to sit an examination for a University assignment. You could even describe certification as a form of cash-for-honours. Similar to the system of Notified Bodies used to certify gas appliances for installation and use in the EU. In my view the latter have failed to prevent patently obvious risks such as the recent BEKO cooker and Flues-in-Voids scandals that have rocked the industry and continue to rock the industry. Certification bodies are never wholly impartial and we should always be mindful of that. Scrolling back in history some of the earliest examples included injection damp proof course treatments. The manufacturers train the installers, supply the materials and hope everyone gets it right. At the end of the day those who spend the most on products will be more favourably treated, good or bad. The product used in my cavity walls is no doubt fit for the purpose. The certification model offered appears weak to me as a professional. I would prefer peer-review by an impartial source at least. Having said that, the huge issue with cavity wall insulation in particular is the difficulty of inspecting work once it is completed. More on all this again. I intend a tutorial very soon on my method of checking cavity wall insulation work. It is incredibly cheap and simple with the right guidance. That is the top-down inspection of the cavity wall from internal window boards. Where incomplete cavity wall insulation work is being investigated, the area below windows is always the most likely area where insulation will be missing. Once loss is proven using this method, the customer can then pursue the installer with confidence and without the expense of thermography. I found an ethical and co-operative thermographer willing to tailor the service to my needs to keep costs down (I have a duty-of-prudence). Not everyone will be so fortunate. 28.04.2013 - I have received a helpful response from the British Board of Agrément (several days ago) in answer to questions. Significantly they have confirmed that: Quote - Directional nozzles are intended to be rotated through 360 degrees - End of Quote. I have obviously asked for further details on this as it only answers part of the question and will need to be expanded for County Court purposes as well as my own. It will be obvious to professionals looking in, as it is to me, that turning the directional nozzle during the course of the work is of fundamental and crucial importance. However in no case I have seen (at my home or elsewhere) has the nozzle ever been turned in any way during the course of the work. I have watched other homes near me being injected more recently. If you have yours done, you watch as well. You do not need to be a Building Surveyor to watch that. Next time I see one being done I will film it through my wildlife photography long-lens and Canon 7D set on video, then you can all watch it on this website. Maybe then the penny will start to drop with any sceptics. If anyone local knows of a job soon to start, let me know. I can film clearly at a discreet 50 metres working from a gimbal head. The BBC or Trading Standards etc could do the same. Historically Surrey Trading Standards have an excellent record of pursuing rogue traders, mindful of rules-of-evidence. A pity others cannot follow their example. 09.08.2013 - As I fully expected, British Gas dirty tricks have started. In fact they started some time ago but I have been too busy to report to you all. I always seem to be apologising for delays in updating but the fact is I have a life to live like everyone else. Much of my time – circumstances permitting – is devoted to wildlife photography and I have been immersed in that seven days a week for the past several glorious weeks. That will continue. Processing images can take almost as long as the day out shooting sometimes. Inevitably there was an attempt to befuddle me with 22 carat waffle about alleged trademark infringement. I anticipated that before I built the website. I received an email from an American company on the subject. I have produced a PDF file with the title ‘CORRESPONDENCE’ which contains, first a copy of the incoming email, followed by a verbatim copy of the text of my response. Finally there is a list of the recipients of that email from me as that list is relevant to the issue. More about the latter again. Since then the bullies have been trying to shut down the website by various rather naïve means. That includes trying to befuddle my web host and 123-reg into shutting down the website. Both have had the courage to check the facts carefully (which they have to do); the website is of course wholly legal, carefully designed as such and will remain so. Having seen the written detail of those attempts I can only describe them as amateurish, naïve and somewhat pathetic. People at that company have my deepest sympathy if that is the only way they can earn their daily bread. Tragic indeed. At the moment the ball is in my court but progress will have to wait for the next overcast day. Proceedings are being prepared against the BBA for reasons which will become apparent soon but some will already have guessed. NOTE: (I adore this one) Someone with an alleged complaint against British Gas in re cavity wall insulation has claimed a representative has told them they only ‘sponsored’ the contractor and has allegedly asked the customer to deal directly with the contractor. If true or if this applies to you, ignore it. The law is clear. If you paid British Gas then they are wholly (100%) responsible. They cannot fob you off unless you let them. Don’t believe me, ask the Citizens Advice Bureau. |

|||||||||||