|

Diary of a dissatisfied customer |

| |

|

| |

| Top-Down Survey Tutorial |

|

This may all seem obvious to some but it could give confidence to others less experienced should they have reason to suspect there may be issues with their own cavity wall insulation. Some may like the idea for peace of mind, perhaps carrying out a check just before redecoration.

It is not nice believing you are contributing to energy conservation only to discover you have been ripped off. Especially so in my case where the perpetrators have knowingly ripped me off, secure in the knowledge they will never be discovered.

That of course has all now changed and anyone can more easily check their own installation. We know about thermal imaging but it is not a readily accessible option for initial DIY exploration. People could perhaps work with others as part of a small group of householders, pooling resources and expertise. In some areas there are already groups of people busy working together in support of energy conservation. They could own and loan the necessary equipment.

This effort could ultimately help drive up standards of cavity wall insulation and standards certainly need driving up. The current system is exposed to widespread abuse and corruption. Inspection holes could be introduced prior to cavity wall insulation work to check the process as work proceeds. Members of such groups could even have their own inspectors inside a home when someone is having the work carried out. Only the householders / inspectors initially would be permitted to check the internal inspection holes in window boards.

This tutorial begins with an overview followed by more detail. If you are considering the idea, please read the whole of the page first.

|

| |

Overview |

|

The top-down survey simply involves drilling a hole through internal window-boards (cills) and inserting a small inspection camera which records information. The main problem of course is damaging the window board and making good afterwards. With the right tools shown here, a perfect remedy is available. |

| |

|

|

The only two items not likely to be found in the average DIY tool box, a plug-cutter (illustrated left) at around £10 and a plug and play endoscope, around £80 (lower down the page).

I have been using plug-cutters for years, principally for disguising fixings made through hardwood. I could not advise drilling your window boards until you have had some practice on pieces of scrap timber. That applies especially to hardwood. You will however learn quickly.

The advantage with this technique is that the repaired hole (through which the endoscope is inserted), is ultimately made good using a piece of timber with matching grain orientation which is glued then sanded to produce an excellent finish, for touching up with paint.

|

|

| |

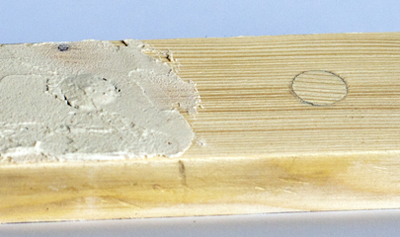

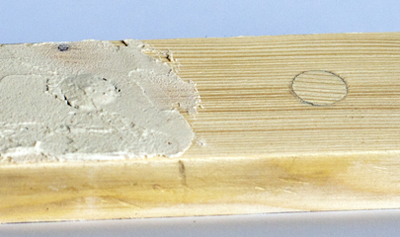

This image on the right shows two holes filled in cheap softwood. One filled with a glued wooden plug produced by the plug-cutter and one filled with a typical filler made from powder. The wooden plug was sanded down immediately after insertion and is ready for painting. The deliberately overfilled second hole will be sanded when the filler has thoroughly dried. The hole containing filler will require filling in two-stages, be porous and harder to decorate. It will require sealing prior to painting, if it is not to show.

The wood filled hole will quickly become invisible and will remain stable in the future. The filler will loosen in time.

The reliability of this wooden-plug technique opens up a new world for cavity wall insulation investigations. Housing Associations can use the technique quickly and cheaply at voids. The speed of this technique will enable them to get the void property re-let within their usual strict time-scales.

|

|

|

|

| |

|

|

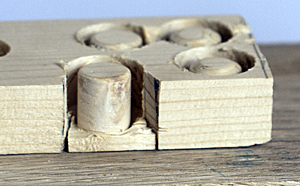

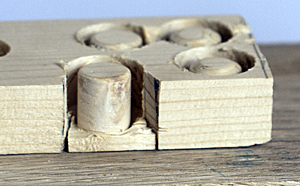

The image on the left shows the plugs produced by the cutter above. The side has been cut away from one so you can see the depth and shape in this 18mm thick piece of cheap softwood. Note the rounded top edge to ease fitting into the hole. The hole must be carefully cut using a matching size bit.

In hardwood (which may be varnished or polished) it is especially important to use a very sharp bit as shown on the right of this right-hand image. For painted softwood a sharp flat-bit will do fine as shown on the left of the right-hand image. Remember that on hardwood great care and skill is required to achieve a high quality finish but it can be done with practice. |

|

|

| |

|

The endoscope shown above is a plug and play device that will hook up to your laptop. There is of course lots of free software or you can use one of the big-name programs. For plug and play I much prefer the windows live movie maker which is basic but ideal for this purpose. Simple and effective. Once plugged in you are recording by default and can then easily edit your production. You can even take a snapshot with one click, to produce an image for insertion into a report. My endoscope is similar to the one shown with a 600mm semi-rigid wand. It is possible to add prisms but once voids have been discovered, anything more is a bit academic.

|

|

Practical Advice |

|

|

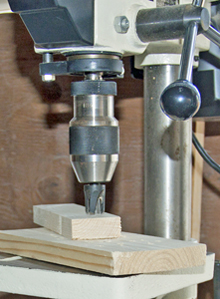

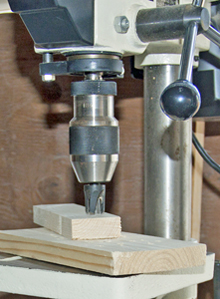

The only risk associated with this process relates to cutting the plugs. I am experienced enough to use the plug-cutter in a hand-held drill, with the wood held fast in a vice. You may not be sufficiently experienced. Ideally you should use a pillar-drill and most people know someone who owns a pillar-drill. If you are part of a group of people pooling resources, a large number of plugs can be cut at one sitting using a pillar drill. I typically use scraps of brand-new deal or pine. You could also cut some plugs using MDF for MDF window boards.

For hand-held cutting, secure the timber in a vice and avoid loose or baggy clothing. Hold the cutter firmly on the timber before you pull the trigger on the drill. Maintain firm pressure.

The drill bit used must be accurately sized to suit the plug cutter. The plug-cutter manufacturer should advise on the correct size of bit. I personally prefer the right-hand bit shown above. The sample shown above is cheap softwood with holes cut using a flat bit. Deal is better and using an ultra sharp bit the final outcome is amazingly accurate, with the grain in correct alignment.

I prefer to let the glue (white wood glue) set before planing and sanding. Finish with a fine sandpaper once planed. If the plug is tapped gently down far enough you can use coarse sandpaper then fine sandpaper, without the need to plane. It is then a quick job to touch up with paint to provide a permanent invisible solution.

|

|

|

|

| |

|

|

NB: I keep my plug-cutter and bits in separate padded bags to ensure they remain ultra sharp. The slightest hint of damage will impair the quality of the plugging process. Once the window board has been drilled part way, you can use an older bit to break through. If there is any risk of damge to the bit in the process, the older bit will suffer and not the ultra sharp bit.

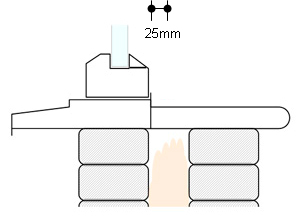

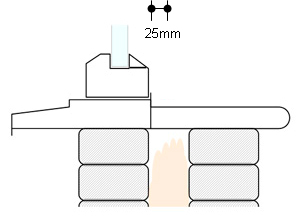

I would generally expect to be drilling approximately 25mm in from the inside of the window. You can of course use both a tape measure and calculation to ensure you drill into the cavity of the wall. The image on the left can only be a guide.

There are now many plug and play endoscopes on the market at various prices. They have built-in lighting, either IR or LED. My semi-rigid endoscope wand enables me to curve the wand slightly so it can look sideways once inserted into the hole. That said, if cavity wall insulation is missing, it will be immediately obvious and once you have proof, you can move forward from a position of strength, especially if part of a group.

|

|

| |

My guess is that the bead and granule cavity wall insulation option is more fluid, will suffer less from friction and will therefore be less prone to sabotage by incompetent installers. I would be pleased to hear from anyone with feedback on this. Nothing except close supervision will protect consumers from deliberate fraud, as happened in my case. Remember, we now know the industry is prone to abuse and corruption that will never be resolved from within.

We have to protect ourselves for no one else will do it. Those that could or should speak out will never do so. What George Orwell once referred to as the 'cowardice of aquiesence'. Shame on them. This method above is entirely legal, ethical, practical and cheap. If any group wants a hand to get started, let me know.

|

|

|

|

|